Case Studies

See how Mate Precision Technologies works with our customers around the world to overcome complex fabrication challenges, increase efficiency and bring visions to life.

-

Hitting The Target

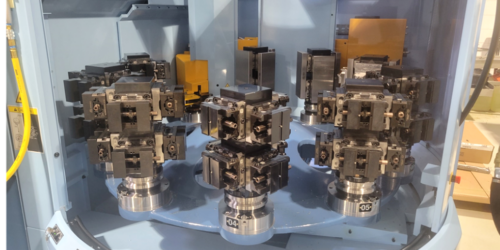

A major firearms manufacturer was dissatisfied after using its existing workholding system for several years.

-

No Movement. No Chatter. No Waste.

John Robinette of United Machine was annoyed. United Machine manufactures numerous parts for the aerospace industry, where quality and consistency are paramount.

-

Unprecedented Service with Custom Engineered Solution

Resolve Surgical Technologies wanted to achieve maximum productivity in its operations.

-

Set-Up, Part-Load Time Decreases 50%

A leading manufacturer of precision metal products reduced its set-up and part-load times by 50% when they switched to Mate workholding.

-

Setup to Bending in 10 Seconds

Mate’s latest case study features another great example of how to increase throughput and reduce labor costs. Mate Regional Sales Manager Peter Visser was visiting a customer that did multiple press brake setups per day. These setups took about 10 minutes each and the customer, Bilan Metal Works, was looking for a better solution.

-

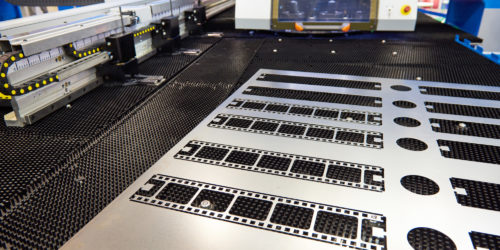

Take a Big Bite Out of Operating Costs: Eliminate Nibbling

One of the most inefficient, frequently overlooked fabrication techniques is nibbling large holes with a small punch. One of the problems nibbling causes is rough or scalloped edges that require secondary operations. Post-punch rework is a common practice in sheet metal fabrication shops, but it doesn’t have to be this way.

-

RapidSet™ Adds $41,600 in One Swift Move

When Mate’s sales engineer spotted a manufacturer spending an inordinate amount of time on tool set up, he recommended switching to RapidSet™ canisters. Doing so added $35,000 in increased capacity and generated $5,730 in annual savings from improved grind life.

-

One Simple Tool Recommendation Adds of $160,000 of Value

Mate’s in-field sales support uncovered a slug pulling issue. Switching to Mate Slug Free® dies added over $160,000 in value for this manufacturer of commercial food handling equipment.

-

Fully-Guided Tooling Adds Over $200,000 of Green Light Time

When the world’s leading manufacturer of ice and beverage systems switched to Mate’s Ultra TEC fully-guided tooling, they realized an additional $200,000 per year in annual green light time.

-

Set Up Time Reduced 20 Minutes per Job

A leading manufacturer of truck and SUV accessories had been using a laser to produce parts featuring its company and product logos, which were very complex. They wanted to produce a higher yield within a specific run time.

-

Major HVAC Manufacturer Saves $100K Annually

When a major HVAC manufacturer started buying newer Amada EM-series punch presses, they standardized on Mate Ultra TEC tooling an reaped the rewards.

-

Circa Metals

Circa Metals is both a contract manufacturer for leading companies and a manufacturer of electrical and communications equipment enclosures. The company acquired two Prima Power punch presses with the intention of streamlining operations and…

-

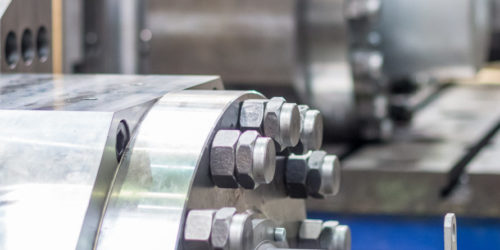

Hydraulic & Mechanical Equipment Manufacturer

A global manufacturer of hydraulic and mechanical equipment serving a wide array of industries wanted to reduce the amount of time…

-

Red Dot Corporation

Red Dot Corporation was having trouble producing a louvered part efficiently.

-

HVAC Manufacturer

A key manufacturer of indoor HVAC systems was experiencing problems with tool setup and maintenance…

-

Elevator Manufacturer

An elevator manufacturer replaced their existing punch presses with Trumpf-style presses.

-

Steel Door & Cabinet Manufacturer

A manufacturer of steel doors and cabinets wanted to save money on spot welding, and contacted Mate to offer a solution.

-

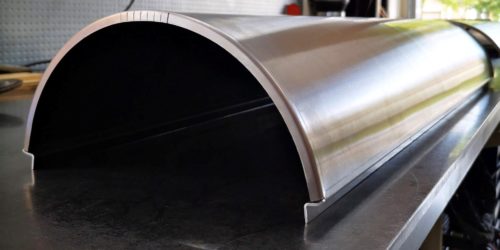

Salesforce Transbay Transit Center

Opened in Spring 2018, the Salesforce Transbay Transit Center in San Francisco is a completely reimagined…

-

Laicor Fixtures Fabrication

Our sales engineers at Mate have years of experience on the shop floor. We are inspired by supporting our customers achieve their vision…

-

Firelake Manufacturing

It’s no secret that eliminating secondary operations improves throughput and reduces costs—positive additions that every manufacturing company…

-

Integrated Metal Products

After 29 years of steady growth, Integrated Metal Products (IMP), one of Canada’s premier fabricators, required more space to keep up. The company…

-

HVAC Equipment Manufacturer

Increased machine uptime and tool life are always at the top of an opportunities for improvement list. Mate’s sales engineers have years of experience…

-

Midwest-Based Fabrication Shop

An independent, Midwest-based fabrication shop wanted to increase the capacity of their punch press operations. They turned to…

-

Fireplace Manufacturer

For sheet metal manufacturers, scrap is often a source of wasted profits. Because scrapped parts need to be made again, scrap is…