Burr Removal with Straightline Deburr

An Economical Way to Eliminate Burrs at the Turret AP Style Title Case

The Problem:

The punching process frequently causes burrs on sheet metal parts. Handling parts with these sharp edges can be hazardous for both operator and end customer. Removing burrs typically requires a secondary operation such as a straight line sander that adds time and cost to the fabricating operation. Further complicating matters are when the burrs are in tight corners, making removal even more time consuming. Mate can help you eliminate these secondary operations and improve safe material handling with a Straightline Deburr tool.

The Mate Solution:

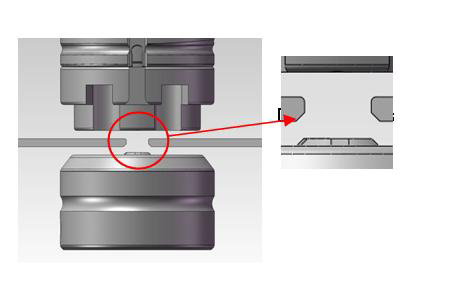

As its name implies, the Straightline Deburr tool is designed to economically deburr metal in a straight line. It’s easy to set-up and program, and perfect for tight corners. The Straightline Deburr tool uses a raised area on the die that is angled at 20 degrees and coins the burr back into the material’s fracture area. The 20 degree angle helps prevent sideways movement of the material or parts. Straightline Deburr is typically used in an Auto Index station or as two tools set at 90 degrees to each other.

While Straightline Deburr is not material thickness specific, it is parting tool specific. The tool should be designed to use with a specific width parting tool when deburring immediately adjacent parts. It can also be used to deburr a single side or the interior of a rectangular opening.