Separating Parts from Material: EasySnap™

Solution Bulletin

Using Easysnap™ for Quick, Clean Parts Separation

The Problem:

Fabricators use a variety of methods to separate multiple parts from a sheet of material. A frequently used method places small tabs between parts by programming the spacing of a slitting punch. While the tabs keep the parts intact during punching, they can be difficult to remove and often leave rough or sharp edges that usually require a secondary operation to remove.

The Mate Solution:

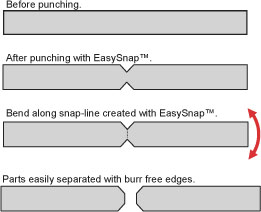

Using a Mate EasySnap™ tool (below) solves these issues because it allows you to build in a way to snap parts out of sheet metal without using a slitting or punching tool. EasySnap allows fabricators to simply snap punched components out of sheet metal by hand, making the life much easier. Since EasySnap leaves a clean, smooth edge, there is no need for secondary operations.

EasySnap uses a V-line stencil machined onto the face of the upper and lower tools. As the tools penetrate the sheet, they create a line of weakness (snap-line) in both surfaces of the sheet metal. The sheet metal can then be snapped apart by bending the material along the snap-line. The actual depth of penetration and force required to snap the part is dependent on the ductility and thickness of the material being punched. It also keeps parts removal easy since the parts simply snap off the sheet.

How Customers Use Easysnap:

- Temporary paint hook. Run the part through the paint line, then simply snap off the unneeded part. Eliminates scratching, extra hooks and is easier to run.

- Leave a blank in for a window part that can be separated at a later step in the manufacturing process.

- Breaking down the skeleton into smaller parts for easier, neater disposal.

- Press brake back stop locator for smaller parts. Simply snap off at the end of the press brake operation. It’s safer, faster, and more accurate…eliminates “eyeballing”. (Right).

- Easier processing of smaller parts.

- Clean, smooth edge after separating parts.