Non-Spring Loaded Forming

Solution Bulletin

The Problem:

Embossing (round or shaped) operations are commonly used in sheet metal and vary in purpose and function. Occasionally, there isn’t a large enough station in the turret to accommodate the emboss too l or the shape exceeds the design parameters of the desired station.

l or the shape exceeds the design parameters of the desired station.

The Mate Solution:

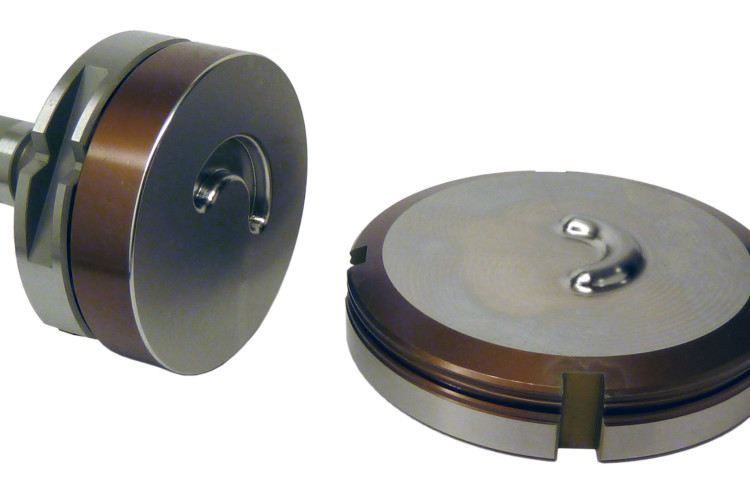

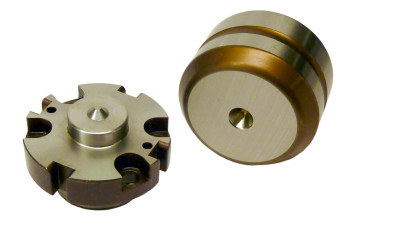

A non-spring loaded tool is ideal for these situations. A larger form can fit into a smaller station because there is no need to allow room for the spring and stripper. Non-spring loaded tools may be form up or form down. The side angles need to be a maximum of 45 degrees to come out of the tool. Shallow forms are also an ideal application because spring loaded stripping is not needed and doesn’t provide a benefit.